Gold and silver coins workshop

The profession of minter appeared in Gaul with hammer striking in the fourth century B.C.

In 2015, an event marked the life of this workshop: a woman started her training as a minter (the first!). The press long since replaced the hammer. The know-how of the minter, their knowledge of the tools, engraving and metals, their expertise passed down from generation to generation without discontinuity remain the same, ensuring the excellence of the productions.

Subliming gold and silver

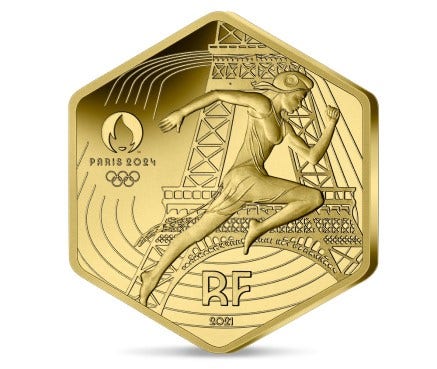

If within the Pessac factory, Monnaie de Paris mints 850 coins per minute and per machine, in Paris, more than a day is required to mint the same quantity. This workshop works exclusively with gold and silver: it transforms the blanks into small series (coins, medals and decorations). It mints the currencies in proof quality. The tools thus present nuanced colours ranging from mat to mirror polished, giving the finished object an extremely precious appearance.

Optimal quality which drives excellence

After having precisely calibrated their press, the minter ensures the quality of the strike and must detect the slightest defect with the naked eye, imagining the rise of the metal compared with the desired relief. The air in the press is filtered and is in overpressure to eliminate anything that could engrain the coins: the motif struck must be perfect! The profession of minter necessitates training of around one year during which the more experienced transmit their knowledge.

Striking tests and complex manufacture

At the heart of innovations, the minter validates the technique to be used and carries out striking tests which are used to test the tools. Their expertise enables any improvements to be made for a perfect result. They manufacture all complex or innovative products (convex, concave, gold insert or colour insert or ceramic-like material, specific form, etc,).

Explore all the faces of Monnaie de Paris

-

-

Break into our plant in Pessac

Pessac plant strikes approximately 1 billion circulating coins at Pessac, half of it is for the export market

-

Online shop

Discover all our products

Buy online our latest collection ! Secured payment and fast shipping

-

Learn more about our craftmanhip

Thanks to their state-of-the-art know-how, our creative craftsmen shape precious ores, engrave style and time in metal and manufacture medals, awards, decorations...

-

Learn about our thousand year history

Monnaie de Paris is France's longest standing institution and one of the oldest enterprise in the world

-

_19th_century.jpg)